When Nissan launched its latest Infiniti model, Nissan required engine dress and front marriage tooling that could cater to existing Infiniti variants as well as support the introduction of the new model.

We had previously supplied an adaptive tooling and intelligent pallet system to Nissan for engine dress. Because of our system’s flexibility we were able to supply new adaptive tools for existing pallets. In total, 150 new adaptive tools were required.

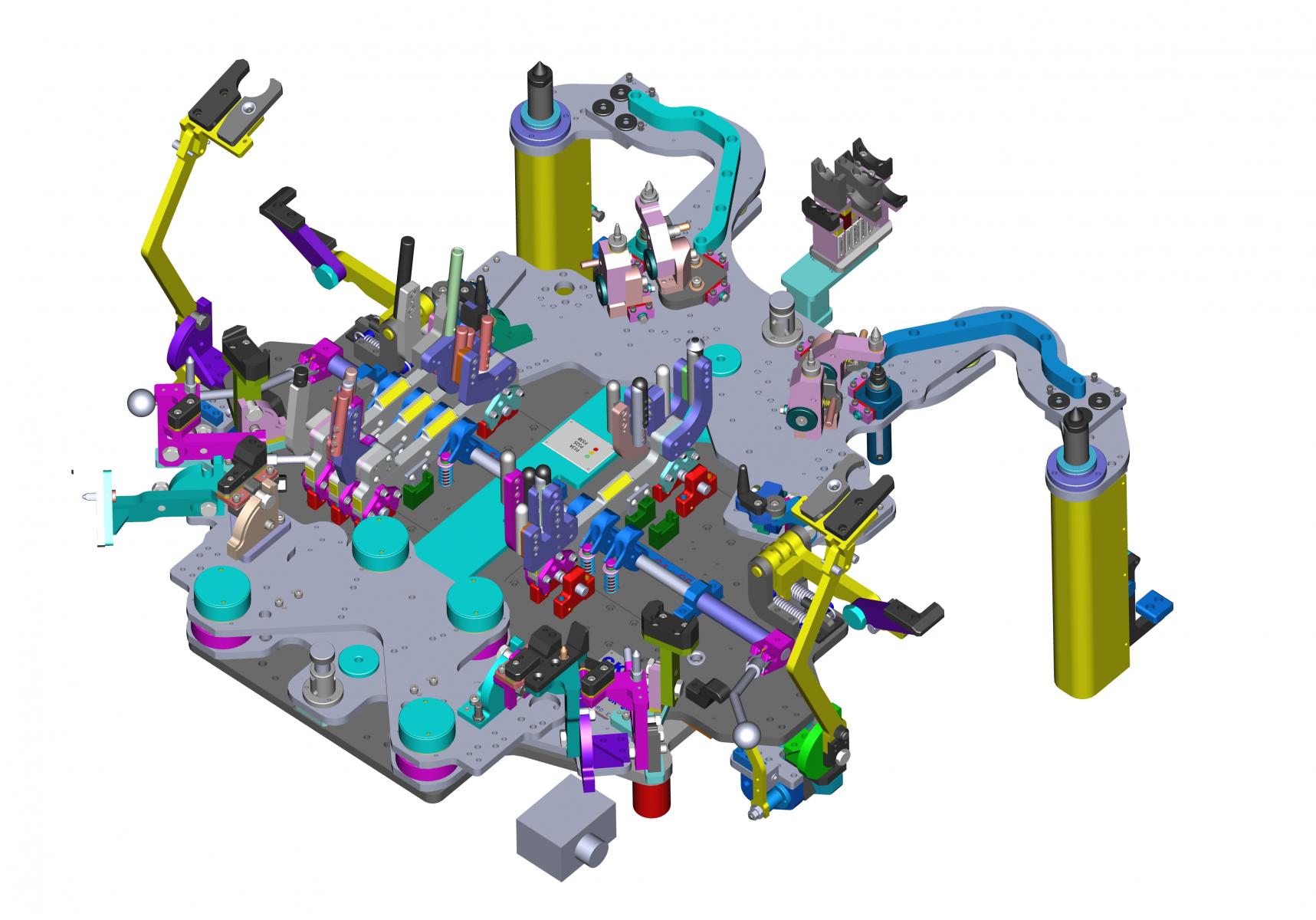

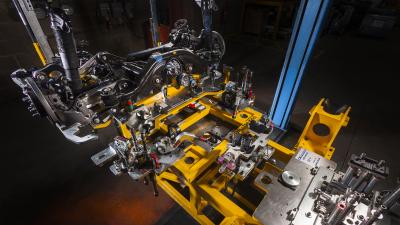

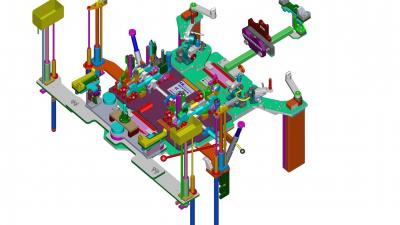

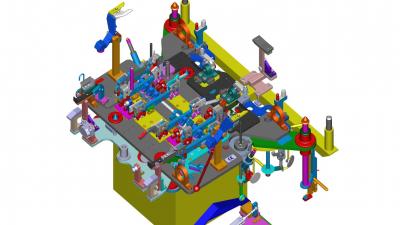

JLR needed to accommodate three Infiniti models with front marriage tooling, and the business asked to design and manufacture the all-new tooling. The tooling was designed as an adaptive tool fixture to ”future-proof” new engine and gearbox combinations. We provided Nissan with a one-off prototype fixture and six new adaptive tools for tryout on-site prior to volume manufacture. The final tooling order was for 19 fixtures and 198 adaptive tools. The new design included new lower control arm supports, prop shaft supports, fixed decking pins and subframe support, as well as numerous other modifications.

The complexity of the new tooling required modifications to the current rear axle pallets. We designed and manufactured all-new pallets that included new lower control arm supports, a sliding decking pin, pre-location pins and subframe supports, as well as numerous other new additions.