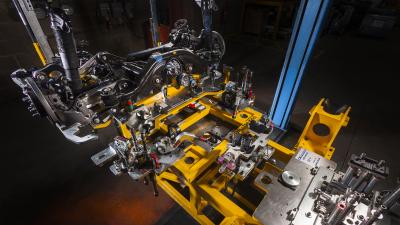

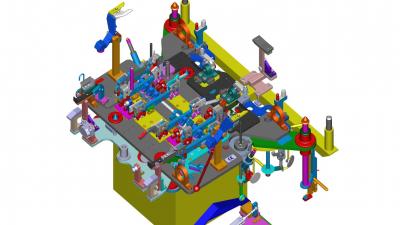

Most of the tooling and equipment that Leidos Industrial Engineers designs and manufactures is dimension critical; i.e., alignment of the master vehicle and engine locations is critical. To adhere to specifications and strict tolerances, we inspect tooling with one of two dedicated in-house coordinate measuring machines (CMM) or with a FARO Technologies FaroArm.

Option 1

Our original CMM with a table size of X: 3500 mm, Y: 2000 mm and Z: 1300 mm. This CMM is retained for larger jobs.

Option 2

Automated LK G80 machine with a bed size of X: 1500 mm, Y: 1000 mm and Z: 580 mm.

Option 3

Portable CMM with reverse engineering capabilities

Inspection FaroArm Platinum

Our 7-axis FaroArm Platinum offers a portable (in-house or on-site) CMM service. The FaroArm allows parts to be verified on-site in a production environment or during assembly before shipment. Reports can be generated continuously as data is gathered. FaroArm inspection can measure to an accuracy of ±0.052 mm. We currently deploy 8-ft and 12-ft FaroArm Platinums.