To accommodate new XE/XF/ F-Pace and Range Rover Sport vehicles, Jaguar Land Rover installed two new vehicle platforms in its Solihull, West Midlands, plant known as the D7A and the D7U that required the design, manufacture, supply and installation of these intricate fixtures.

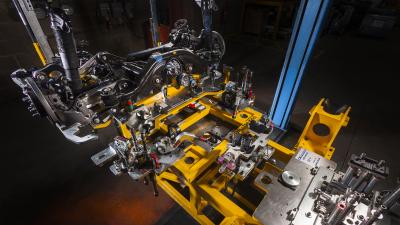

The fixtures are known as ”dogbones” due to the shape of the frame that holds the tooling. Each D7A and D7U platform has a dedicated dogbone designed to support the engine and gearbox variant being built.

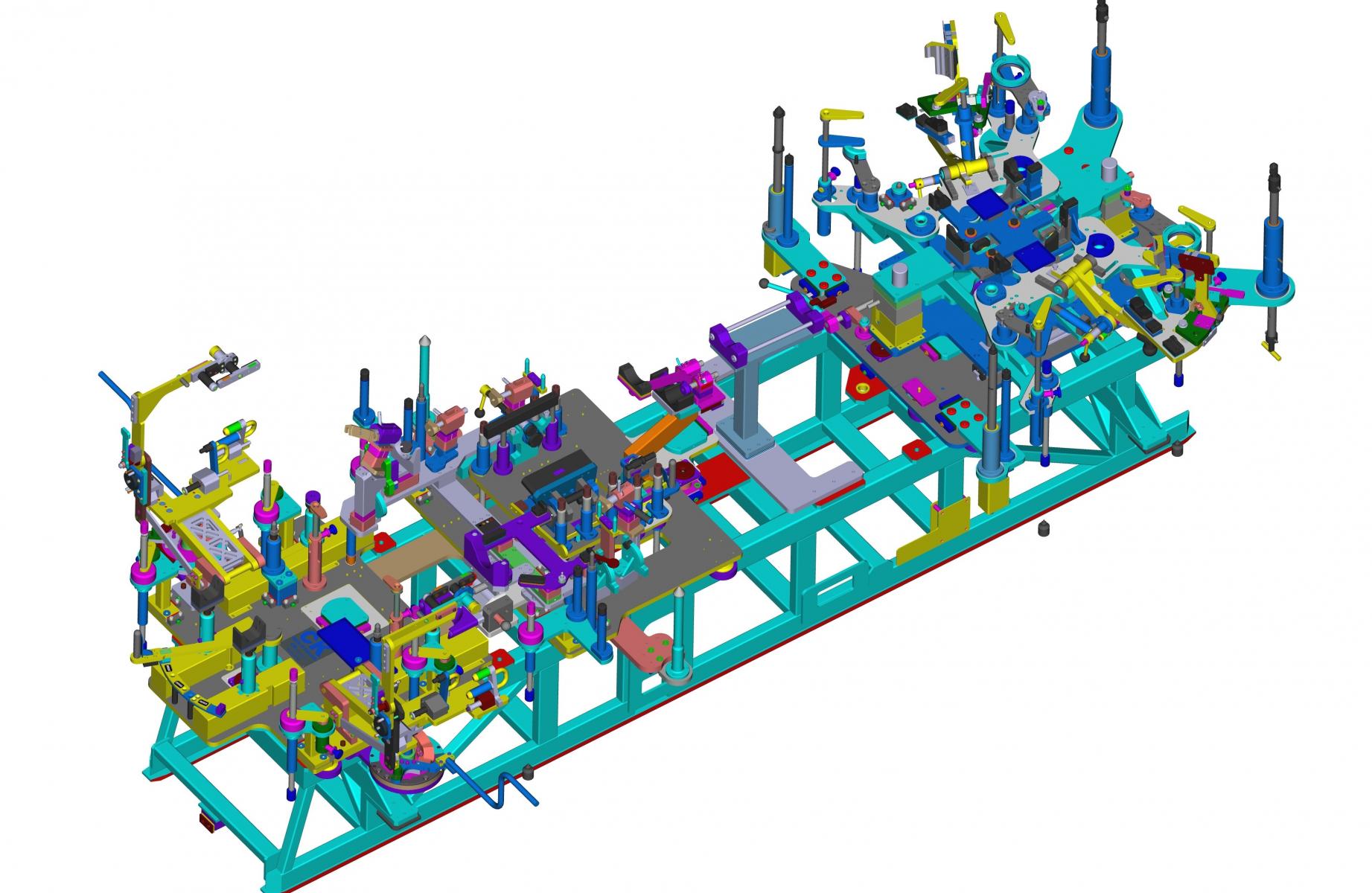

We have supplied 59 D7A dogbones and 59 D7U dogbones to JLR for the platforms. In addition, 13 “Fead” pallets have been provided to support AJ126, AJ200 and GTDI engines and relevant transmissions/transfer boxes.

Although the D7A and D7U dogbone designs differ, each includes:

- A rear floating plate section that can be locked in a central nominal position. The plate can be unlocked during the decking process by a mechanism within the marriage station.

- Lower control arm supports that can support the LCA and knuckles at various heights during assembly.

- Rear clamps for the tightening processes to ensure a stable position during build operations. The clamps are released after the build process is completed and prior to marriage.

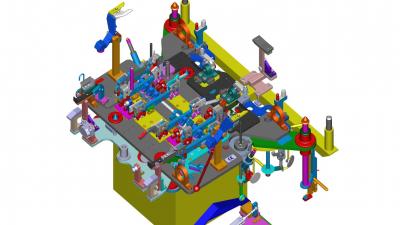

Our Fead pallets for JLR include;

- Main base frame to support all features and aid transfer process

- Static engine support plate with all required adaptive tool systems

- Rotating gearbox and transfer plate to allow 90-degree rotation.

- Conventional (static) tooling to support the transfer box

- Fixed FDU tooling to support interface locations